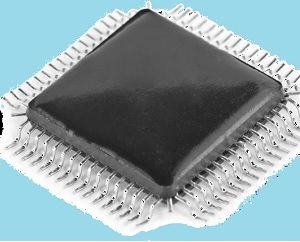

GLOB-TOP MATERIALS FOR CHIP-ON-BOARD (COB) CHIP PROTECTION

WITH SECOND GENERATION OF MODIFIED EPOXY COMPOUNDS

Traditional underfill and glob-top materials with anhydride curng epoxies have Tg around 100-150°C that may exert too high interfacial tensile stress when going through reflow soldering at 250°C. A new generation of AIT underfill and glob-top compounds with different chemistry enables a new paradigm of performance in ultra high Tg of 240°C and incorporating high thermal conductivity and low thermal interface resistance to power the transfer of heats from both the top and bottom sides of the flip-chip packages. Please CLICK HERE TO VIEW VIDEO for details of AI Technology’s Underfill And Glob-Top Encapsulant Products in enabling higher performance flip-chip and chip-on-board devices.

Properties of Lid-Seal Adhesives and Glob-Top Encapsulants

| PROPERTY | MC7865-GT (Glob-Top Encapsulant) | MC7685-GTS(Glob-Top Encapsulant) | LESP7670-HF (ESP7670-HF) (Lid-Sealing) | LRTK7660-HF (RTK7660-HF) (Lid-Sealing) |

| Electrical Resistivity | >2X1014 Ω-cm | >2X1014 Ω-cm | >5X1014 Ω-cm | >2X1015 Ω-cm |

| Viscosity @5.0 rpm /Thixotropic Index | 60,000 cps/2.5 | 60,000 cps/2.5 | 65,000 cps/4.0 | 65,000 cps/4.0 |

| Material Form Factors | Syringe and Frozen Storage | Syringe and Frozen Storage | B-Stageable at 50-70°C to dry preform | B-Stageable at 50-70°C to tacky preform |

| Customizable Parameters | Viscosity and Thixotropic Index | Viscosity and Thixotropic Index | Conductive and/or Thermally Conductive | Conductive and/or Thermally Conductive |

| Glass Transition Tg (°C) | 240 | 175 | 130 | 165 |

| Device Push-off Strength (psi) | >3500 | >4000 | >3000 | >4000 |

| Hardness (Type) | ~ 90D | ~ 90D | ~ 90D | ~ 85D |

| Cured Density of Conductive Adhesive Portion (gm/cc) | 2.5 | 2.5 | 1.6 | 1.6 |

| Thermal Conductivity | > 2.0 W/m-°K | > 1.8 W/m-°K | > 0.20 W/m-°K | > 0.20 W/m-°K |

| Thermal Expansion Coefficient (ppm/°C) | 18 (X-Y=Z, Isotropic) | 19 (X-Y=Z, Isotropic) | 35 (X-Y=Z, Isotropic) | 35 (X-Y=Z, Isotropic) |

| Maximum Continuous Operation Temperature (°C) | > 250 | > 200 | 150 | 150 |

| Decomposition Temperature @5% weight loss (°C) | >450 | >450 | >450 | >450 |

| Recommended Curing Temperature/Time (°C/min.) | >125/60 | >125/120 | >150/30 | >150/30 |

With the additional dimension of adding high thermal conductivity and low interfacial thermal resistance in the underfill and glob-top compounds, thermal dissipation of components generating heat can be assisted with thermal slug and in case of underfill material for the flip-chip components, heat can be dissipated via the provision at the front side of the flip-chip in additional to the traditional backside of the chip.

For more information and recommendation assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or 1-800-735-5040 (EST) and Fax: 609-799-9308