AI Technology offers a wide array of adhesive solutions for component and substrate bonding and boasts one of the most comprehensive film and paste adhesive lines to help our customers build their products with the greatest reliability at the lowest cost of manufacturing. Our patented phase-change thermal pads, thermal greases and gels, and thermal adhesives have also set many performance and dependability benchmarks for power semiconductor and modules, computer, and communication electronics.

Click the links below to learn more about our line of cutting-edge products and view more in-depth information:

AIT Solutions

Since pioneering the use of flexible epoxy technology for microelectronic packaging in 1985, AI Technology has been one of the leading forces in development of advanced material and adhesive solutions for electronic interconnection and packaging for various industries.

Automotive Electronic Thermal Interface Material (TIM) & Adhesives

With over 30 years of experience in inventing and formulating specialty adhesives for electronic applications,

AIT provides the most comprehensive line of thermal interface solutions that are engineered to facilitate manufacturability and throughput.

Electric Vehicle (EV) Battery Manufacturing Materials

With over 30 years of experience in inventing and formulating specialty adhesives for electronic applications,

AIT provides the most comprehensive line of thermal interface solutions that are engineered to facilitate manufacturability and throughput.

Die Attach & Thermal Interface Materials for Laptops & Tablets

What distinguishes AIT’s CPU, GPU and memory modules electronic adhesives and thermal management material solutions from the competition is our proven low thermal resistance and unparalleled long-term reliability.

.

Conformal Coatings

What distinguishes AIT’s Conformal Coatings is their unparalleled ability to adhere to any component on a printed circuit board (PCB) or printed wiring board (PWB) while inducing zero stress and providing outstanding moisture, protection.

.

Cool-Gelfilm™ SZM

COOL-GELFILM™ SZM is a new class of thermal interface materials that dispenses in place like a film but has the performance and characteristics of a grease-gel.

.

Cool-Grease™ ZXM

COOL-GREASE™ ZXM is a modified oxide filled, electrically insulating thermal grease which exhibits outstanding thermal transfer in comparison to other thermal greases.

.

Cool-Silver™ G4

COOL-SILVER™ G4 is the fourth generation, lower thermal resistance version of AIT’s popular COOL-SILVER™ Grease.

.

Cool-Silver™ Pad

COOL-SILVER™ PAD is a micro-silver filled, non-electrically conductive, thermal interface material for thin and thick gap filling applications.

.

Die-Attach Film (DAF) Adhesives

Die-Attach film (DAF) adhesive has become a necessity when stack chips are used to accomplish larger capacity in 3-D packaging of flash memory devices. The push now is for even thinner insulating die-attach adhesive that can properly handle interfacial stresses in stacking chips with bond-lines as thin as 8-10 microns or less to help mobile devices to achieve even lower profiles.

.

Underfill, Glob-Top Encapsulants, Lid-Seal Adhesives & Conformal Coatings

What distinguishes AIT’s Underfills, Glob-Tops, Lid-Seals and Conformal Coatings is their unparalleled ability to manage stress while providing an outstanding moisture barrier. These capabilities are achieved with unconventional polymer engineering and designs.

.

Package Level EMI/RFI Conformal Shielding Solutions

With over 35 years in providing EMI/RFI shielding coating and sealant to military electronics, AIT has extensive experience providing solutions for these component package level shielding applications.

.

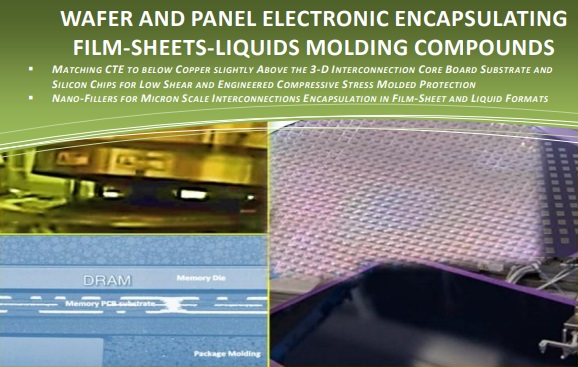

Wafer & Panel Electronic Encapsulating Film-Sheets-Liquid Molding Compounds

With over 35 years in providing EMI/RFI shielding coating and sealant to military electronics, AIT has extensive experience providing solutions for these component package level shielding applications.

.

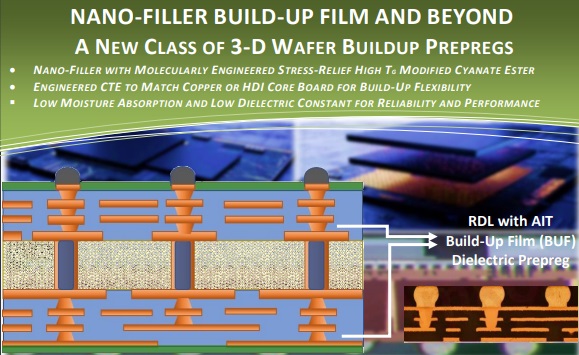

Nano-Filler Build-up Film

Nano-filler with molecularly engineered stress-relief, high TG modified cyanate ester, engineered CTE to match copper or HDI core board for build-up flexibility, and low moisture and low dielectric constant for reliability and performance.

.

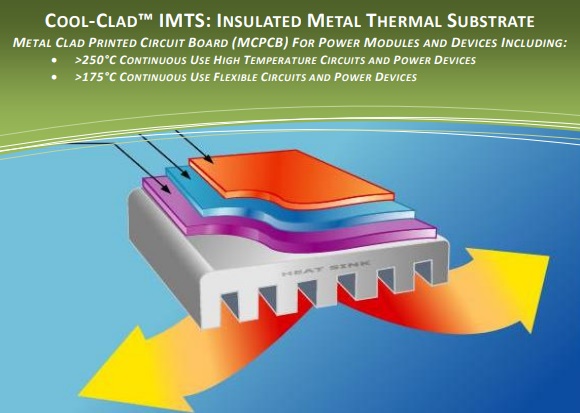

COOL-CLAD™ IMTS: Insulated Metal Thermal Substrate

Insulated metal thermal substrates have been used to replace direct bonded copper (DBC) substrate for power modules and devices mostly for cost and flexibility. The effectiveness of the insulated metal, such as aluminum or copper as a thermal substrate, hinges on the dielectric adhesive layers to provide high thermal transfer from the POWER generated by the semi-conductor chip or component while maintaining high dielectric insulation.

.

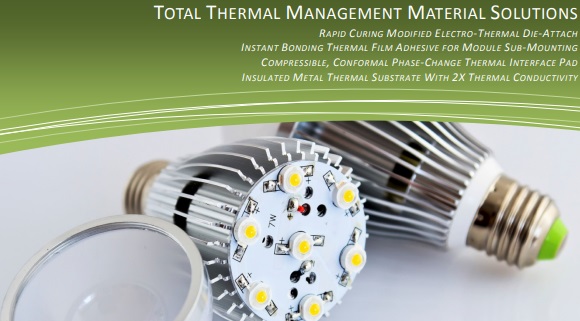

LED Total Thermal Management Solutions

What distinguishes AIT LED total thermal management material solutions is their unparalleled, proven low thermal resistance in the die-attach, sub-mount and heat-sink, long-term reliability after years of thermal shock and cycling, and molecular structures that are engineered to prevent “drying” or cracking inside the materials and along the interface surfaces.

.

Cavity Electronic Packaging with Near Hermetic Lid-Sealing Adhesives

What distinguishes AIT’s FLUOROSEAL® cavity electronic packaging lid-seal adhesive in comparison to the traditional epoxy lid-seal adhesive besides its molecular structure designed to block moisture and corrosive gases from penetration is its production workflow cycle friendly for batch and inline production.

.

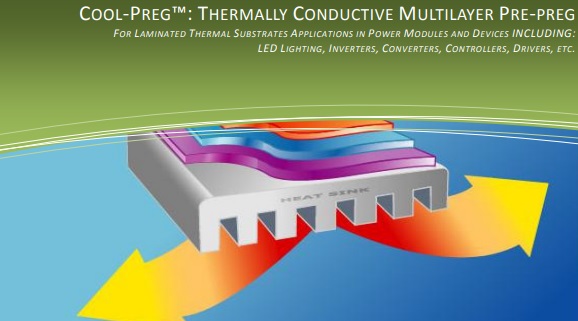

COOL-PREG™ Thermally Conductive Insulated Prepreg

COOL-PREG™ provides the possibility of making multilayered circuits with a substrate such as COOL-CLAD™ (AIT insulated metal thermal substrate) or other third-party material, including making your own in-house insulated metal thermal substrates.

.

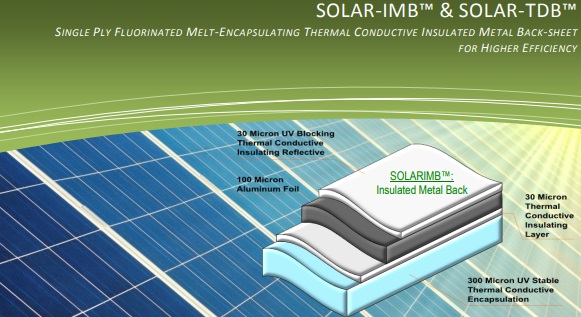

Cavity Electronic Packaging with Near Hermetic Lid-Sealing Adhesives

AIT SOLAR-IMB™ (insulated metal solar back sheet) and SOLAR-TDB™ (thermal dissipative solar back sheet without metal layer) back sheets are thermally dissipative thermoplastic laminates that provide instant melt-encapsulating capability for the backside of the solar modules while providing mechanical strength and electrical insulation as good as that of T/P/T.

.

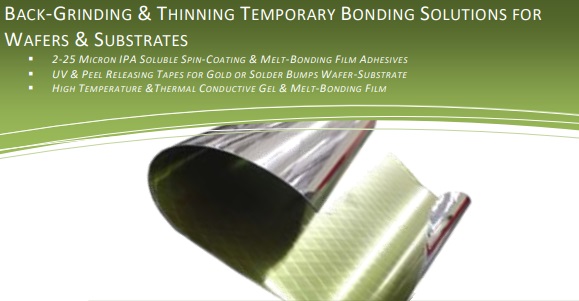

Temporary Bonding Solutions

In addition to our proven record of usage achieving unparalleled feats of high vacuum, high temperature and low thermal resistance, AIT temporary bonding adhesive solutions are the most comprehensive material solutions innovated and manufactured in the United States. AIT has some of most advanced materials and experienced chemists in formulating and customizing temporary bonding materials and solutions for critical semi-conductor and microelectronic operations of thinning wafers for superior performance.

.

Underfill Solutions

AIT’s Underfills are designed with molecular structures to provide unparalleled ability to provide compressive stress for chip and component soldering interconnection while absorbing planar shear stresses during thermal cycling and operations.

.

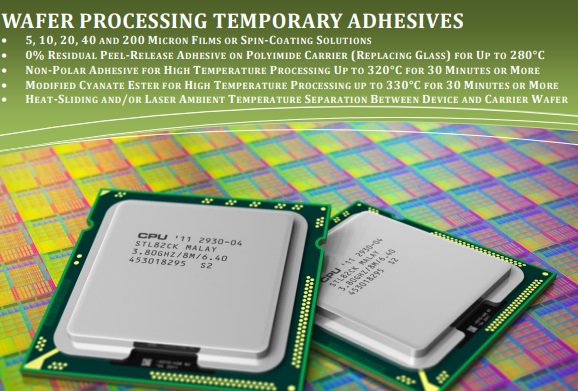

Wafer Processing Temporary Adhesives

AIT is the first known to provide a film format of its high temperature temporary bonding adhesives for thin wafer processing. Leveraging its expertise of film adhesive manufacturing for the semiconductor industry for more than 30 years, AIT’s wafer processing adhesives are available from 5 micron to 80 micron for device wafers up to 450mm with and without topography.

.

Wafer Processing & DAF Adhesives

AIT’s temporary bonding tapes are engineered for high reliability for wafers and substrates with extensive bumped features or flat with nominal or no features. Integrated with wafer and dicing tape mounting equipment for reduced processing time and costs per wafer, the also offer higher performance (including DAF with thermal and/or electrical conductivity).