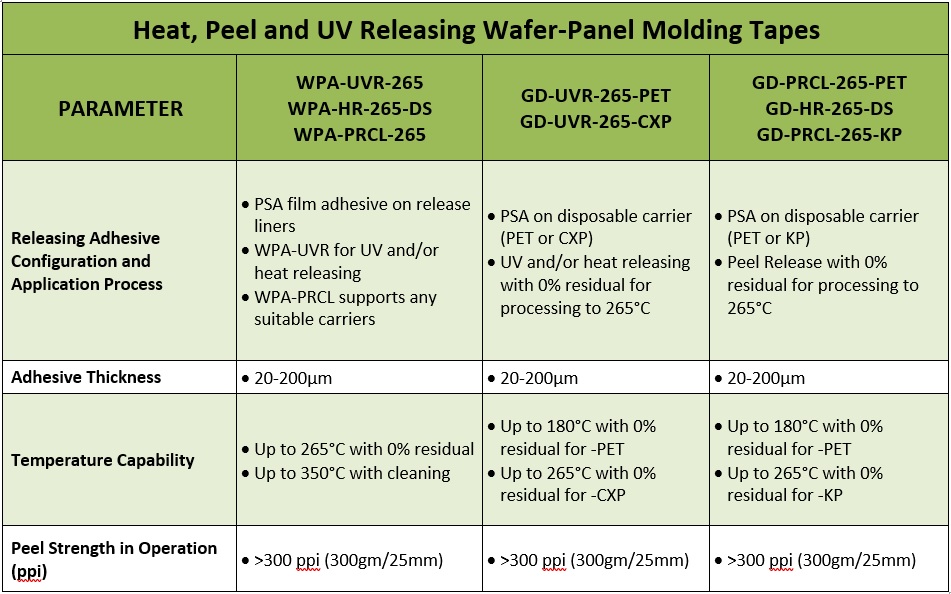

• Patented novel adhesive technology solutions for “clean release” no-clean molding release for panels up to 650mm

• Flexibility in production use with pressure-sensitive adhesive integrated high temperature disposal carrier or double-sided adhesives for use with glass-wafer carrier

• Proven clean release technology allows for no-clean, high temperature processing and molding up to 265°C

• Release adhesive layer is available from 20 to 200 µm in thickness for bumps and features of different heights and widths, up to 650mm

• Release adhesive layer can also be ordered as heat releasing, UV releasing, or peel releasing to meet all processing requirements

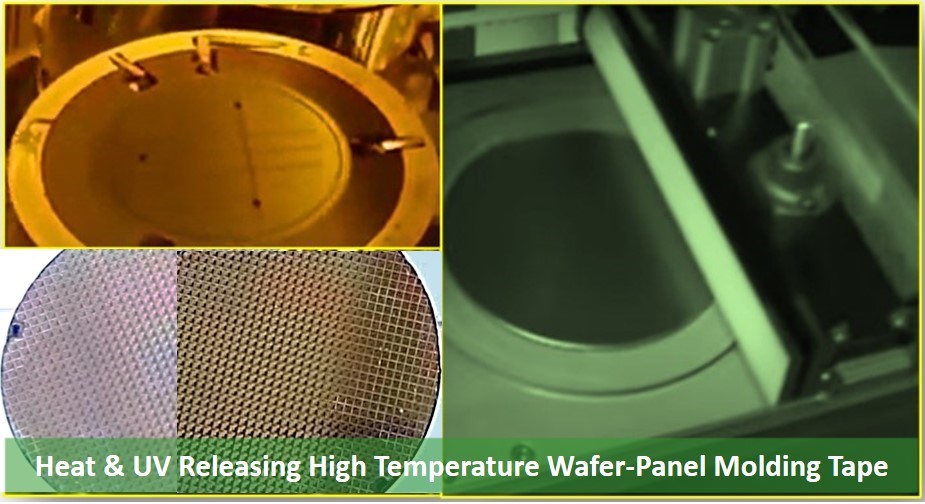

Patented novel “clean release”, “no-clean” pressure sensitive adhesive film-tapes for fan-out wafer and panel level 3D heterogeneous integration molding release applications. AIT innovated solutions include heat and/or UV release types with integrated disposable flexible carrier or double-side adhesive type for use with glass or wafer carrier. All of these AIT molding support adhesive tapes are applicable for processing and molding up to 265°C without residual upon release removal.

Novel and patented (US 11,222,864) temporary bonding and releasing adhesive technology for wafer and panel level processing in fan-out and heterogeneous integration. Ideal for large area wafer and panel molding encapsulation.

Temporary Bonding and Releasing Film and Liquid

• PSA film on release liners for use with glass or other carriers

• Proven applicable for processing up to 265°C and yet release clean for no-clean processing. Minor cleaning for processing up to 350°C

• Available on flexible disposable carriers for ultimate productivity

Precision Chip-Component Placement and Positioning

• Pressure-sensitive at ambient temperature for ease of chip positioning

• High shear bonding for molding stability

Compatible with Wet and Dry Processing

• Acid plating bath and water-based cleaning

• Maintain high shear bonding for drilling and mechanical grinding

AIT temporary bonding and mold releasing tape solutions have been engineered to include processing capability post molding and before releasing. The high shear bond strength makes them suitable for mechanical and laser via drilling and grinding operation. The adhesive bonded wafer and panel can be directly used in acid bath plating operations. The adhesives can also withstand post-molding operation up to 265°C for “residual free” release and intermittently up to 350°C under inert condition with some minor residual and cleaning.

Fast and Residual-Free No-Clean Releasing

• Compatible with molding compound in post-molding releasing u

• PRCL-series for peel release on carriers including metal foils with 7-11ppm/°C CTE

• UVR-series for rapid UV flash release without residual on glass or PET UV transparent carriers

• HR-series for heat-releasing after molding