BACKGRINDING & THINNING TEMPORARY BONDING TAPE ADHESIVE SOLUTIONS for WAFERS and SUBSTRATES

- UV, Heat & Peel Releasing Adhesive Tapes for Bumped Wafer or Substrate

- High Temperature and Anti-Static for More Reliable Operations

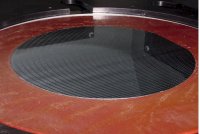

Wafers requiring grinding and thinning to 50 microns needs high performance adhesion and yet easily release on demand either by UV or heat curing

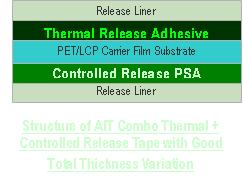

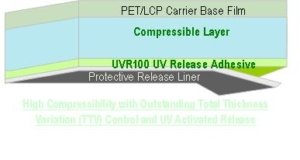

AIT wafer and substrate grinding and thinning temporary bonding adhesive tapes are made in the United States with Company Service Centers in China and USA. The high temperature controlled release tape has a conformable compressible layer of 150 and 300 micron thickness to accommodate bumped wafers with gold or solder bumps respectively.

AIT UV releasing temporary bonding tape adhesives offer options of different operational bond strength and PET or LCP carrier base film for operations at 150C and 250C respectively.

Properties of AIT BACK-GRINDING TAPE ADHESIVES for Bumped Wafers

| PARAMETER | BG-UVR100-PET | BG-HTCR100-PET | BG-HR200-PET |

| Release Mechanism-Material and Thickness | UV Exposed | Controlled Peel | Heat Curing Release |

| Carrier Support Film and Thickness |

|

|

|

| Thickness of Compressible-Compliant Layer |

|

|

|

| Peel Strength in Operation (gpi) |

|

|

|

| Peel Strength for Release (gpi) | 25 gpi nominal | 100 gpi nominal | 25 gpi nominal |

| Operational Temperature Capability |

|

|

|

| Chemical Resistance | Outstanding | Outstanding | Outstanding |

| Water Jet Resistance | Outstanding | Outstanding | Outstanding |

| Note #1: All backgrinding and thinning temporary materials are free of silicones or siloxanes. | |||

| Note #2: Anti-static versions are available for all UV, heat or peel release temporary bonding. | |||

Made-In-USA Wafer Back Grinding and Substrate Tape Adhesives For Worldwide Applications

AIT high temperature back-grinding tape adhesives are unique in the industry for maintaining consistent bond strength to wafer at temperatures as high as 200°C. Both UV-releasing type and high temperature controlled peel strength types are available for optimizing specific applications.

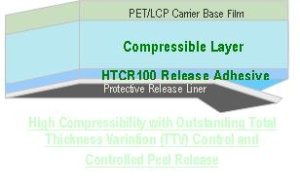

High Temperature Grinding Tape Adhesives with Controlled Release

Anti-static, controlled peel strength adhesive tapes for up to 300°C intermittent use

Major Distinguishing Characteristics:

- Can be used intermittently for up to 250°C and under some specific strong etching solutions.

- Absolutely silicone-free and 0% contamination transfer before and after dicing operation.

- Holding on diced parts even after prolonged exposure to and immersion in water.

- Same peel strength before and after transportation after more than 30 days of mounting.

- Inherently anti-static, independent of ambient moisture conditions.

- Tight tolerance of controlled release within 25% of peel strength specification for controlled manufacturing.

- 150 micron and 300 micron adhesive-compliant layer to accommodate gold-bumped and solder-bumped wafers for accurate and stress-free thinning.

| AIT Product | Adhesion Strength (Peel, gm/in) | Adhesive/Buffer Thickness (Micron) | Backing Material Thickness (Micron) | Compressibility [ ] | Tensile Strength (Kg/cm) |

|---|---|---|---|---|---|

| BG-FC-HTCR 250 (Single-Sided) | 250 | 150 | 125 | [>50 micron] | >200 |

| BG-SB-HTCR 500 (Single-Sided) | 500 | 300 | 125 | [>250 micron] | >200 |

| HTCR 250-GDS (Double-Sided) | 250 | 150 | 125 | [>50 micron] | >200 |

| HTCR 500-GDS (Double-Sided) | 500 | 150 | 125 | [>50 micron] | >200 |

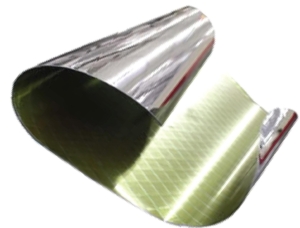

UV Activated Release Grinding Tape Adhesives

Anti-static, controlled peel strength tapes for up to 100°C intermittent use

Major Distinguishing Characteristics:

- Can be used intermittently for up to 100°C and under some specific strong etching solutions.

- Absolutely silicone-free and free of contamination transfer before and after dicing operation.

- Holding on diced parts even after prolonged exposure and immersion in water.

- Same peel strength and UV activated releasing property before and after transportation after more than 30 days of mounting.

- Inherently anti-static, independent of ambient moisture conditions.

- 150 Micron and 300 micron thick adhesive-buffer layer for gold-bumped and solder-bumped wafer thinning.

- Tight tolerance of controlled release within 25% of peel strength specification for controlled manufacturing.

NOTES:

- Other thicknesses may be made to special order.

- All of the compressible backing films based are proprietary technology, high temperature stable, and non-silicone flexible thermosetting resins.

- Some of the adhesives may tolerate strong acid etchant.

| AIT Product | Adhesion Before UV Exposure (Peel, gm/in) | Adhesion After UV Exposure (Peel, gm/in) | Adhesive/Buffer Thickness (Micron) | Backing Material Thickness (Micron) | Compressibility [ ] | Tensile Strength (Kg/cm) | Special Characteristics |

|---|---|---|---|---|---|---|---|

| BG-FC-UVR500 | 500 | 20 | 150 | 125 | [>100 micron] | >200 |

|

| BG-SB-UVR500 | 500 | 20 | 300 | 125 | [>250 micron] | >200 |

|

Melt-Bonding Wafer-Substrate Dicing Film

Major Distinguishing Characteristics:

1. Absolutely silicone-free.

2. All adhesives may be removed and free of contamination transfer after dicing operation.

3. Holding on diced parts even after prolonged exposure and immersion in water.

4. Same peel strength and removal property before and after transportation for more than 30 days after mounting.

5. Inherently anti-static, independent of ambient moisture conditions.

6. Tight tolerance of controlled release within 25% of peel strength specification for controlled manufacturing.

| AIT Product | Push-Off Strength (Die-Shear, psi) | Max. Load Bearing Temp. (°C) | “Melt-Bonding” Temperature & Lamination Process (@14-15psi) |

|---|---|---|---|

| CB7060 (Single ply melt-bonding adhesive film) | >1,000 | 60 |

|

| CB7130 (Single ply melt-bonding adhesive film) | >1,000 | 130 |

|

| CB7350-S (High-tack single-sided adhesive film on a temperature stable liner) | >300 | 150 (Continuous & 300 @5 min.) |

|

| CB7350-B (High-tack double-sided adhesive film on a temperature stable liner) | >300 | 150 (Continuous & 300 @5 min.) |

|

| CB7065 (Thermally conductive, single ply melt-bonding adhesive film) | >1,000 | 60 |

|

| CB7135 (Thermally conductive, single ply melt-bonding adhesive film) | >1,000 | 130 |

|

| TK7355-SS (High-tack single-sided adhesive film on a high thermal conductivity film liner) | >300 | 150 (Continuous & 300 @5 min.) |

|

Parts may be removed at temperatures same or higher than the lamination temperatures of 70°C for CB7065 and 130°C for CB7135. Follow by suitable solvents (Please consult AIT engineering for assistance) for complete dissolution cleaning. Proprietary cleaning solvent is used to remove diced parts for TK7355. Part-on-liner may be placed on a suitable wire-rack and soaked in solvent bath sequence for complete dissolution and cleaning of adhesive residue.

For a recommendation, information or assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or 1-800-735-5040 (EST) and Fax: 609-799-9308