New Generation of Ultra High Tg Film Underfill

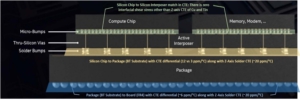

Chip-on-chip with copper pillar interconnections or gold-stud bumps is best with underfill CTE less than copper at 18ppm/°C. Chip-on-package such as BT or equivalent having CTE of 12 ppm/°C is best filled with underfill with CTE as close to 12 ppm/°C as possible. UF-MC7883-FP having below 16 ppm/°C CTE and capillary gap filling capability of less than 35μm meets 3-D and chiplets packaging requirements.

High Melt-Flow Film Underfill for FOW:

- Outstanding melt-flow and wetting to flow-over-wire for stack-chip applications

- Ability to cure at lower temperature from 100-150°C for lower interfacial stresses

- Ideal for large area stack-chip and module

- Preform with specific thickness accommodates the flip-chip or ball-grid-array parts with preformed cut-outs for interconnections allowing the film adhesive to flow and encapsulate for protection

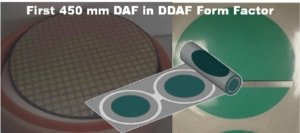

Flow-Over-Wire underfill film adhesive is available in DDAF format for large scale wafer level packaging

Underfill Liquids and Film Adhesives:

| FUNCTION | AIT PART# | THERMAL, ELECTRICAL, & other RELEVANT PROPERTIES |

| Underfill Film Adhesive for Wafer or Chip | UFF-ESP7770 |

|

| Underfill Film Adhesive for Wafer or Chip (REWORKABLE) | UFF-RW-ESP7760 |

|

| Underfill Film Adhesive for Wafer or Chip | UFF-CXP7880 |

|

| Underfill Film Adhesive for Wafer or Chip (REWORKABLE) | UFF-RW-CXP7860 |

|

The ultra-high glass transition temperature (Tg) at 240°C minimizes tensile stress induced failures when the flip-chip packages are going through the reflow soldering of lead-free solder.

For more information and recommendation assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or fax: 609-799-9308