Rework Procedures for Stress-Free Epoxy and Thermoplastic Adhesives

AIT’S flexible die attach, component attach and substrate attach adhesives have a dramatic advantage over the more traditional epoxy attached devices. They can be reworked readily with the application of stress concentration with twisting or torque.

- Continuous Operation Temperature depicts the thermal stability and stable bonding albeit lower bond strength of around 500 psi die-shear at 150C. Thus, it can be continuously used as conductive adhesive with the requirement not exceeding those criteria.

- “Reworkability” refers to lower bond strength at higher temperature and thus with suitable stress concentration, the bonding can be plied off. For example, the bond strength at ambient and lower temperature is over 2000-3000 psi while at 80-150C, the bond strength is lowered to 1000-300 psi. While the bonding strength is adequate for bonding, the lower bond strength can be utilized to “REWORK” expensive devices with stress concentration such as plying from the corner, etc.

- Debond and separate the device and substrate with suitable stress concentration without damaging either one.

- While the same attempt at 2000-3000 psi will likely damage either the device or substrate or both.

Rework of Epoxy and Thermoplastic Adhesive Joints are Primarily Mechanical in Nature

Both epoxy and thermoplastic adhesive bonding can be strong and tough to break. Because of the flexibility built into the polymer network, AIT adhesives tend to be easier to rework at elevated temperature. In some cases, the epoxy network may be swollen with suitable solvent for easier removal. Most of the thermoplastic adhesives may be dissolved or softened with suitable solvent for easier removal and cleaning.

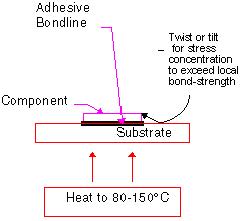

Bond and adhesive materials are easier to break when stresses are concentrated to exceed its tensile or shear strength (Figure 1). Thus torque and peel stresses initiated at corners or some localized points will require much less force and thus easier to perform.

Figure 1. Reworking Procedure with Heat and Stress Concentration

Method 1:

- Heat the bonding area to 80°C-150°C. Heat locally if other components are sensitive to heat.

- Rework should be done using tool that can hold onto the die/component and be able to apply 10 foot-pound of torque. The tool should be able to tilt or twist the component/die, providing a stress concentration up to 500 psi to provide the necessary stress for debonding. Avoid applying stress directly upward if the die or component is sizable (Remember 1 square inch of bonded area will require 100-500 pounds!)

- Remove component/die with tool and stress concentration.

- Apply RS 816 solution on the adhesive residue with suitable tool. Make sure the solution is applied to the residue only. Allow solution to soak and work for 20 minutes or more. Multiple applications of RS 816 can be used if desired. Soaking can be done at room temperature. Remove adhesive residue with a tough nylon brush or equivalent non-abrasive tool.

- Apply new adhesive and bond component/die according to normal bonding procedures.

Method 2:

- Apply RS 816 onto bond-line. Let it soak for 30 minutes or longer. Replenish if appropriate. Adhesive should swell for ease of rework.

- Repeat Method 1, steps 1-5, where step 2 is optional.

For more information and recommendation assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 and Fax: 609-799-9308