SOLAR-THRU™: A Single Ply Fluorinated Melt-Encapsulating PVDF Front Sheet For Instant Melt-Bonding Lamination

At current, high vacuum forming time, costly materials and sub-par performance equates to disproportionately large manufacturing costs for producing solar panels. The physical challenges demand expert solutions and creativity from diverse disciplines to develop a solution.

With over 30 years of experience in formulating and manufacturing of specialty materials and adhesives for electronic applications, AIT has developed a series of fluorinated melt-encapsulating PVDF front and back sheets, UV resistant coatings, sealant-adhesives and conductive tabbing without soldering.

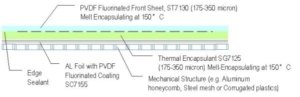

The melt-encapsulating fluorinated front and back sheets are coupled to allow 10 times reduction in vacuum laminating-curing processing time than traditional laminating-encapsulation of solar panels with EVA. With the introduction of SOLAR-THRU™ and SOLAR-THRU™ PVDF, AIT can assist solar panel manufacturers implement inline lamination processing rather than batch based vacuum encapsulation processing.

- Industry’s first low pressure, low temperature and instant melt-bondable thermoplastic encapsulating materials for inline encapsulation with lamination pressure.

- The same pressure lamination at temperatures of 140-160°C will complete the tabbing process of connecting the solar cells in series.

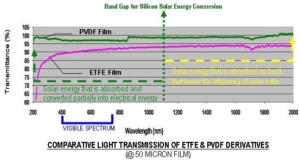

AIT SOLAR-THRU is a PVDF film which, like other fluorinated films, has a high resistance to UV disintegration without the use of organic UV absorbers. The use of this high transparency front sheet allows more spectrum of energy through to allow more energy conversion than the EVA encapsulant. The highest conversion efficiency is achieved without the glass front sheet if mechanical strength can be imparted by the back plane structure.

Front Sheet and Encapsulation Suggested applications:

- 375 micron film configuration for standard solar panel and tab

- 75 micron film configuration for thin film solar front sheet

- 175 micron film configuration for mono- and poly-crystalline solar panel with thin tab of less than 100 micron thickness

| Properties of SOLAR-THRU™ (ST 7130) Encapsulant Front Sheet | |

|---|---|

| Electrical Resistivity | >1014 ohm-cm |

| Dielectric Strength (V/mil) | >750 V |

| Dielectric Constant | 3.5/11 |

| Optical Clarity (Transmission @ 100 micron thickness) | >95% |

| Peel Strength with EVA (Pound/inch, cohesive failure) | >10 |

| Device (Silicon) Push-off Strength on glass (psi) | >1200 |

| Cured Density of Composite Dielectric (gm/cc) | 1.65 |

| Thermal Conductivity | > 0.2 W/m-°C |

| Linear Thermal Expansion Coefficient (ppm/°C) | 90 (X-Y=Z, Isotropic) |

| Elastic Modulus (psi) | 20,000 psi |

| Elongation Before Breakage | 300% |

| Maximum Continuous Operation Temp. (°C) | > 150 |

| Recommended Melt-Lamination Pressure/Temperature/Time (psi/°C/Second) | >15/>150/>0.5 |

AIT patent-pending panel construction and process with thermoplastic melt-encapsulation has the potential to dramatically change the paradigm of solar panel manufacturing without changing the manufacturing infrastructure. The insulating metal thermal back sheet enhances thermal dissipation and solar panel performance on the hottest day.

For a recommendation, information or assistance, please contact AIT sales and engineering:

AIT technical sales and service department can also be reached at: 1-609-799-9388 or 1-800-735-5040 (EST) and Fax: 609-799-9308