Electric Vehicle (EV) Battery Packaging: Thermal, Electrical, Mechanical and Safety Considerations for

Manufacturability Reliability Recyclability

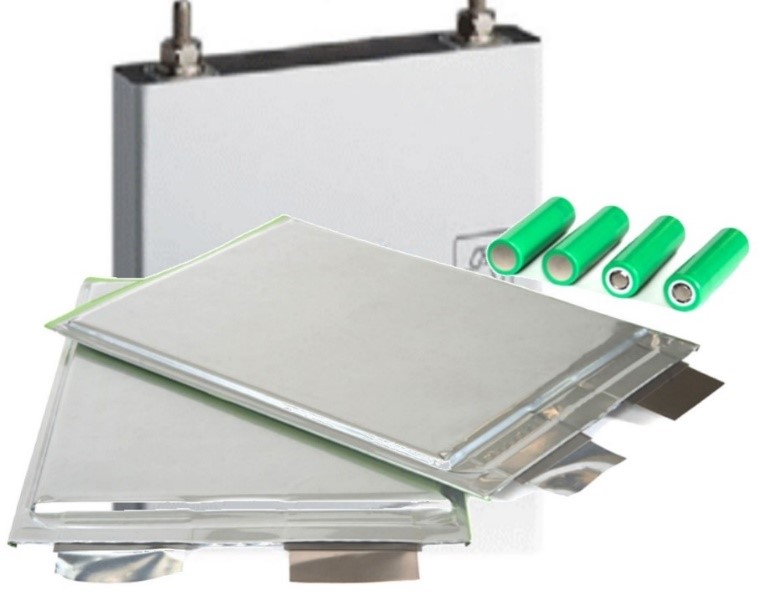

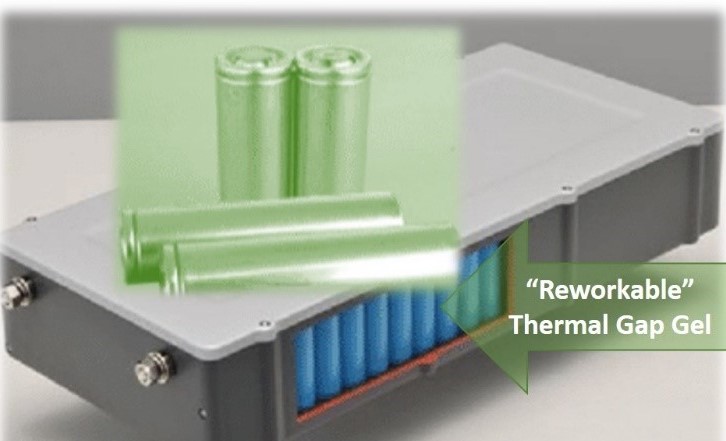

Battery assembly is critical for the powering, reliability, and safety of Electric vehicles (EVs). The packaging and packing from individual cells in the shape of a cylindrical, pouch, and prismatic into final assembly requires the use of different potting, adhesive, and thermal interface pads, to provide the mechanical and thermal interface to achieve reliability and safety.

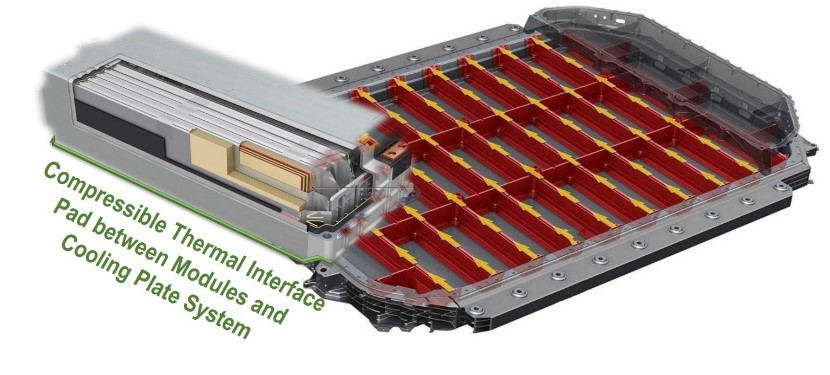

With the weight and volume of battery usages, the disposal of the battery assemblies after its life cycles, ability to recycle the metallic materials used in the battery assembly is also becoming critical and integral consideration.

Unit battery cells from cylindrical, pouch, and prismatic packing into the required high voltage and power EV Battery require different thermal, electrical, and mechanical interfaces along with safety and recycling considerations.

Battery assembly from cells to modules and final assembly requires electrical interconnection and insulation, fire-retardant in safety provision, and thermal interfacing to the cooling system, and mechanical interfacing to the vehicle structure and frame. In the life cycle of the EV battery, the ease of recycling is also a critical and integral part of the design consideration.